Adhesive Peel Tester purchaser|adhesive peel tester : distribute Cutter Type: 6 x 1, 2, 3mm: Coating Thickness: 0 - 250μm (0 - 9.8mils) Packing List: Basic Kit: 1x Elcometer 1542 Cross Hatch Tester*, cutter angle adjustment tool, hexagonal wrench, transit case & user guide Full Kit: Basic Kit plus: . WEBEylül Tumbar. Actress: You've Made Your Bed, Now Lie in It. Eylül Tumbar is known for You've Made Your Bed, Now Lie in It (2023) and Who Were We Running From? (2023).

{plog:ftitle_list}

webVancouver Community College App. Four new ways to stay connected with your campus. Access all your campus information on the go. Keep your classes, assignments and events organized. Join the campus discussion .

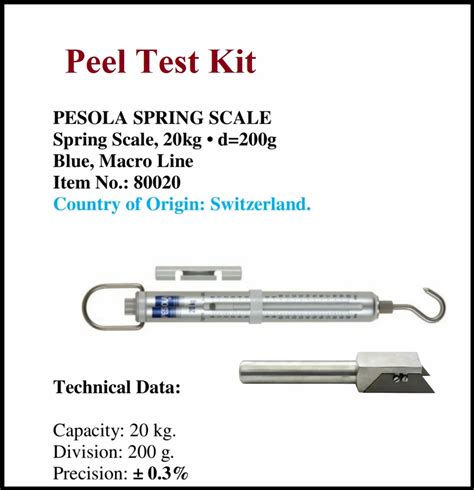

peel testing machine

Some of the more popular test methods that this device is capable of performing: 1. PSTC: 101 (A, B, C, D, E, F), 4, 15, 55 2. ASTM: D 3330 3. TLMI: L-IA1, L-IA2, L-IA3 4. AFERA: 4001 P11 5. FINAT: FTM 1-6, 10, 11 See moreChoose from a variety of peel test machines that meet your specifications and budget. Peel testers, or peel test machines, are universal test machines specially configured to determine .A peel test is a fundamental mechanical test that measures the properties of an adhesive bond. Peel tests involve applying a tensile force to a flexible substrate that is bound by an adhesive to either another flexible substrate (such as .

ASTM D1876 is a test method that measures the peel separation strength of two flexible materials that have been bonded together. This is commonly referred to.

Cutter Type: 6 x 1, 2, 3mm: Coating Thickness: 0 - 250μm (0 - 9.8mils) Packing List: Basic Kit: 1x Elcometer 1542 Cross Hatch Tester*, cutter angle adjustment tool, hexagonal wrench, transit case & user guide Full Kit: Basic Kit plus: .

Peeling takes a wide array of forms. In the most basic sense, a peel test can consist of (1) a laminate comprising of two (or more) layers peeled apart, often at the interface or (2) an adhesively bonded joint in which two substrates are joined by an adhesive layer and then peeled apart, or (3) peeling of a single, adhesive material from a substrate or itself.Adhesive Peel Tester is a Tensile Tester specifically designed to perform the following : 180° Adhesive Peel Test. 90° Adhesive Peel Test. Loop Tack Test. Roll Peel Test. Release Force Test of Silicon Liners; Suitable for : PSA Tapes and Labels. Confirms to : PSTC 101 / PSTC 16 / PSTC 8 / ASTM D 3330PSTC-101 is a standard test method to measure peel adhesion strength in pressure s. FTM-9 Pressure Sensitive Tape Loop Tack Test Equipment. Loop tack tests provide the means of assessing the most important and yet the hard. ASTM D903 180 degree Peel Strip Strength of Adhesive Bonds. ASTM D903 is a standard test procedure to determine the .

ASTM D903-98 is a common tensile test used to evaluate the Peel-Stripping Strength of Adhesive Bonds. Back; Home; Products. Materials Testing. Universal Testing Systems. Automated Testing Systems. . To perform a test to ASTM D903, the adhesive materials must be cut into specimens 1" x 12" long. The specimens are then peeled away from either a .

Various methods of adhesion testing include pull-off testing, peel testing, shear testing, and cross-cut testing. How do you increase adhesion strength? Adhesion strength can be improved by proper surface preparation (such as cleaning, roughening, or applying a primer), optimizing the adhesive formulation, or modifying the curing process. 5.1 These test methods are tools for quality assurance use. Given specific pressure-sensitive tape and a requirement in terms of the minimum or maximum peel value expected for this tape, the data from the test can be used in conjunction with acceptance criteria.

Both of these Test Methods can also be considered variants of the tape-and-peel test, a method for assessing adhesion that has been in use since the 1930s. This test, at the simplest level, involves the examination of the paint film .There are many test methods used to determine the strength of an adhesive including peel, shear, cleavage, and tension tests. Peel tests are common for tapes, labels, coatings, and other bonded materials. There are three main types of peel tests including 90 degree peel test, 180 degree peel test, and a T-Peel test. The LoopASTM D3330 is a major peel testing standard that outlines the requirements for determining the peel adhesion properties of pressure-sensitive tapes such as surgical, electrical, packing, and duct tape. The standard includes 6 different methods (A-F) for measuring peel adhesion with both 90° and 180° peel tests.ADMET’s easy-to-use adhesive peel fixtures are employed by the adhesive industry to test the peel strength, bonding, and shear properties of adhesives. Peel fixtures conform to testing standards such as ASTM D1781, ASTM D3330, ASTM D3167 and can also be customized based on your test application. Below we will explore the types of peel tests .

NOTE 2—Subject to agreement between the purchaser and the seller, Test Method B can be used for thicker films if wider spaced cuts are employed. . D3330/D3330M Test Method for Peel Adhesion of Pressure-Sensitive Tape D3924 Specification for Environment for Conditioning and Testing Paint, Varnish, Lacquer, and Related Materials .values for several variables will be acceptable to both the manufacturer and the purchaser of the adhesive. 1. Scope 1.1 This test method is primarily intended for determining the relative peel resistance of adhesive bonds between flexible adherends by means of a T-type specimen. 1.2 The values stated in SI units are to be regarded as the .

peel testing kit

Adhesion Test Method. A test dolly is bonded to the coating using an adhesive. The Elcometer 106 adhesion tester houses a spring arrangement which applies a lift force to the dolly as the tension is increased. When the coating is pulled . Watch how to properly conduct a T-peel test to determine the relative peel resistance of adhesive bonds. This test is referred to as a “T-peel” test, because.According to ASTM D3330, specimens for the peel test must be prepared from pressure-sensitive tape of a specific size in order to measure the peel adhesion. The exact dimensions of the specimens vary according to the test method within the standard. In general, however, the specimens must be cut to meet the specified width and length requirements to ensure .This test is optimized for tapes with flexible backings, or tapes that are adhered to a similar flexible substrate. Unlike the 180 degree peel test and 90 degree peel test, the T-peel or trouser method is the easiest test to set up and conduct. These types of tests are often done on transfer tapes or at converting companies that may use tape to .

Peel testing typically involves several variables which must be managed in order to ensure consistent and repeatable tests. Those variables include angle of the peel, rate of the pull, pressure with which the adherands are pushed together, and the surface characteristics of the adherands. ASTM D6252 is a common test method to measure the peel adhesion of .

180° Peel Test: The most common test, peeling the substrate away from the adhesive at a 180-degree angle. Ideal for evaluating general bond strength. Ideal for evaluating general bond strength. 90° Peel Test: Similar to 180°, but with a 90-degree peel angle.ISO 8510-1, Adhesives — Peel test for a flexible-bonded-to-rigid test specimen assembly — Part 1: 90° degree peel [3] ISO 5725 (all parts), Accuracy (trueness and precision) of measurement methods and resultsvalues for several variables will be acceptable to both the manufacturer and the purchaser of the adhesive. 1. Scope 1.1 This test method covers the determination of the relative peel resistance of adhesive bonds between one rigid adherend and one flexible adherend when tested under specified condi-tions of preparation and testing.The Peel Seal Adhesion Strength Tester is an innovative instrument which helps in measuring the adhesion Strength or peel ability of self-adhesive pressure sensitive materials. Peel adhesion is defined as the force required to test the strength of the adhesives. . With the purchase of Peel Tester from Testronix , it has become super advanced .

The ADMET eXpert 7601 adhesive and peel testing system has been designed to allow users to perform a wide variety of adhesive tests on a single easy to use and compact instrument. You can confidently report results knowing that the system has been engineered to meet all accuracy requirements specified in major standards organizations including . Peel Strength Testing Peel strength testing is particularly important for testing the permanence of adhesion or peelability of self-adhesive (pressure-sensitive) labels, whether it is important that a label can be easily removed (e.g., after purchase of a product) or not (e.g., to prevent labels from expensive products being switched to cheaper .

by the test operator that any arbitrarily chosen value within such a range or any combination of such values for several variables will be acceptable to both the manufacturer and the purchaser of the adhesive. 1. Scope 1.1 This test method is primarily intended for determining the relative peel resistance of adhesive bonds between ßexible

webJosh Manley Poker. 127 likes · 1 talking about this. Josh Manley Poker ♠️ Poker player & Twitch streamer ♥️ Low- to mid-stakes tournaments ♣️ Guildford/Brighton, England ♦️ Join me for hand.

Adhesive Peel Tester purchaser|adhesive peel tester